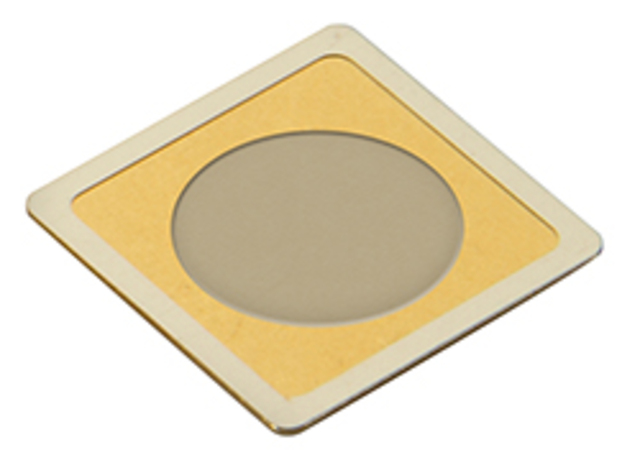

With extensive experience in RF and microwave packaging, Materion is able to offer our patented Epo-Lid™ covers in a wide variety of sizes and shapes to meet your epoxy-coated lid requirements. Our extensive tooling capabilities allow us to design and manufacture new lid designs for various hermetic applications to meet tight customer specifications.

100 EPOXY-COATED LIDS MATCHED TO CERAMIC PACKAGES

We offer ceramic lids that complement our ceramic packages for RF power transistors:

- Lid sizes available from 0.16” x 0.16” to 2.0” x 2.0”

- Lid materials available in ceramic (alumina), metal (plated Kovar) or plastic (liquid crystal polymer)

- Cup lip topography can be plain or include notches or bumps

CERAMIC LIDS OUTPERFORM THE STANDARD

Materion excels at production reliability and repeatability. Our lids are manufactured with a layer of high-quality B-staged epoxy bonded to the lip, and controlled to a thickness of +/-0.0005”.

We partner with you to manufacture innovative Epo-Lid covers, enabling your specific design requirements for RF power transistors.

DURABLE EPOXIES PROTECT CRITICAL COMPONENTS

Materion's MEG 165 forms a strong seal that protects sensitive electrical parts from dust, moisture, and short-circuiting. MEG 165 is optimal for sealing smooth, flat surfaces, and serves as a low-cost alternative to solder. Both epoxies are excellent electrical insulators and prove effective when used in combination with Materion's ceramic Epo-Lid covers.

ULTRA-STRONG ADHESION THAT LASTS

Our superior performing microelectronic epoxy offer excellent adhesion over time for a wide variety of materials including metal, glass, alumina and plated gold, plastics (thermoset and high-temperature thermoplastics), and ceramics. Our epoxy is compatible for use with components made of virtually any material. MEG 165 is also convenient to use, as it does not require the use of a primer.

ADVANTAGES OF MICROELECTRONIC EPOXIES

Materion's MEG 165 are not tacky prior to curing and are supplied B-staged. Once cured, it will pass gross leak hermetic testing.

MEG 165 PROVIDES:

- Low flow upon curing; optimal for flat sealing surfaces

- Standard thickness 0.003” =/- 0.0005” (75 um) over the entire seal surface

- Epoxy is not tacky prior to curing and supplied B-staged

- During curing, epoxy will flow to seal two flat, smooth surfaces

- Extremely durable and convenient bonding for non-hermetic packaging components

Benefits

- Tooled for over 75 epoxy-coated lids in shapes such as square, rectangular, circular, plates, or cups.

- Our ceramic lids sealed with our epoxy provide durable adhesion for the lifecycle of your product.

- Epo-Lid covers are sealed with epoxy that meets or exceeds gross leak hermeticity.

Applications

- RF Transistors

- Microwave Packaging