DOVETAIL CLAD METAL

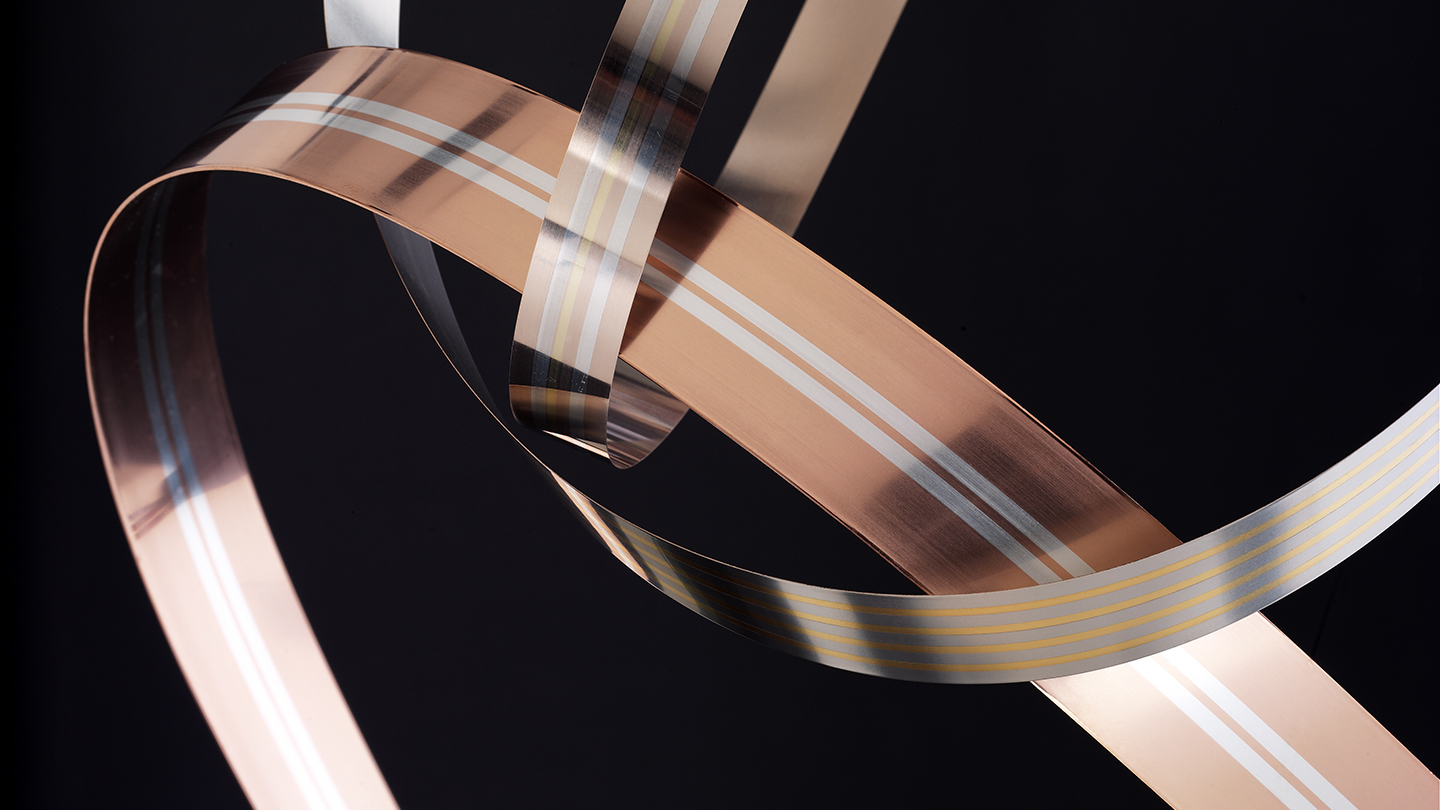

Dovetail Clad Metal

- For high-volume copper-to-aluminum assembly efficiency for lithium-ion batteries. Our patented side-by-side cladding process joins copper and aluminum in long continuous master coils for high-volume, low-cost laser assembly. Low height and narrow joint widths enable compact, flexible designs for bus bar and lead tabs. Learn more about Dovetail Clad® metal.

eSTAINLESS STEELS

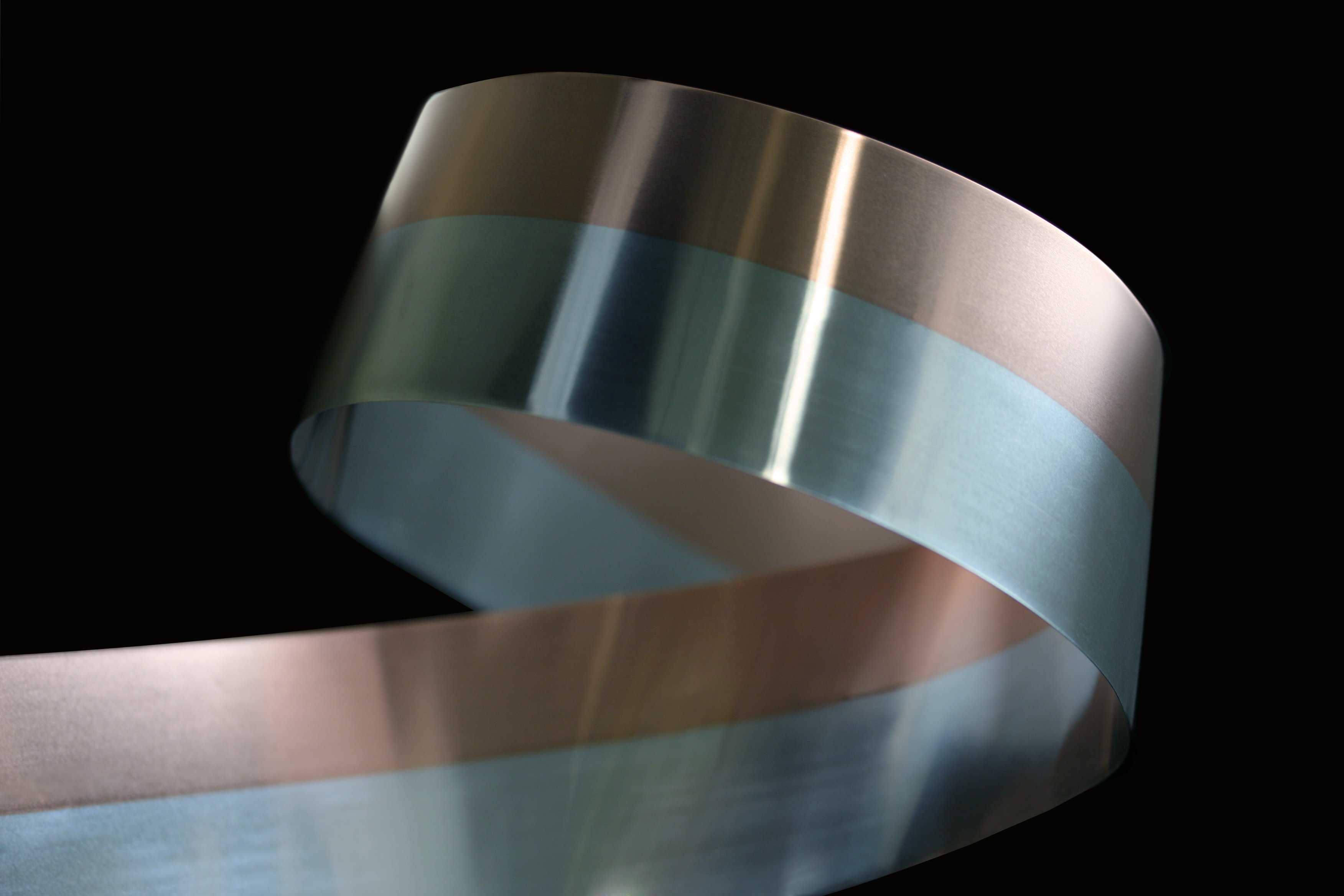

eStainless Steels

- For improved thermal management, our eStainless® clad material enhances performance and reliability by converting structural components into heat sinks. A fully formable copper or aluminum clad metal laminate combined with stainless steel, eStainless material maintains high stiffness with 10 to 15 times greater conductivity than conventional materials. Learn more about eStainless clad.

ELECTRICAL CONNECTOR MATERIALS

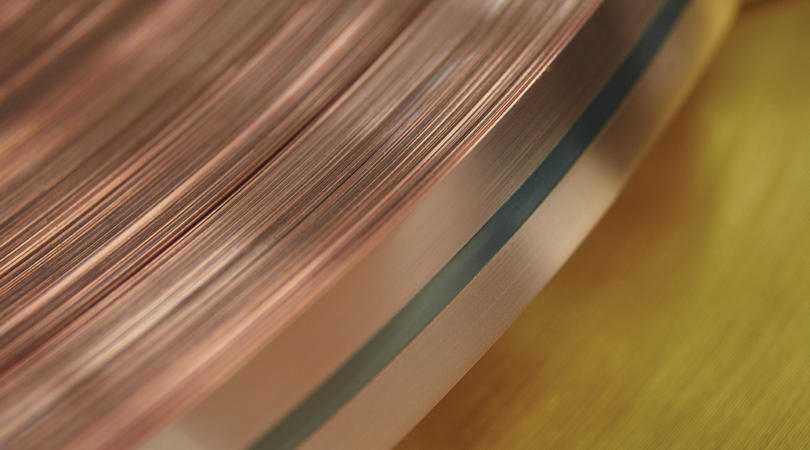

Electrical Connector Materials

- Clad metal and electroplated products provide stable, reliable, long-term performance with minimal signal distortion. See more information about electrical connector materials.

iON EV CLAD

iON EV Clad

- For faster direct current EV charging. Our iON EV™ Clad material can withstand the high current and elevated temperature environment of direct current connectors. The material is highly conductive with enhanced friction characteristics. Get more details about iON EV Clad.